Having just got to grips with the alternator wiring etc I realise that If you fit a VDO tacho they have an adjuster on the rear, connect it let the.

Table of contents

- Rev Counter sensing from alternator - how does this work?

- Get RPM form alternator

- Register Now

- Technical Reference Manual

- Where to connect tach in alternator

Connect the master tach and start the engine.

At about 1,, RPM, use a jeweller's screw driver to carefully adjust the potentiometer in the "CAL" hole about 10 o'clock on the rear of the tach , bringing the tachometer into agreement with the Master Tach. Only a minimal amount of turning is required. Overtorquing of adjustment will damage gauge mechanism.

Turning clockwise increases tach reading, counter clockwise reduces reading. If the tach cannot be brought into calibration, the black Range Selector Switch is probably on the wrong setting. Alternator belt slippage will cause some error on the tachometer. Set rotary switch on tachometer back to the range that includes the number of gear teeth that pass by the Magnetic Pickup in one crank shaft revolution. This information can be obtained from the Engine Distributor or Dealer. Arrow on slot must point to setting; if it is between settings, the tach will go full scale when engine is started.

Final calibration requires a Remote Master Tachometer. Connect Master Tach and start engine. At about 1,, RPM, use a jeweller's screwdriver to carefully adjust the potentiometer in the "CAL" hole about 10 o'clock on the rear of the tach , bringing the tachometer into agreement with the Master Tach.

Rev Counter sensing from alternator - how does this work?

Only a minimal turning is required. Turning clockwise increases tach reading, counter clock wise reduces reading. If the tachometer cannot be brought into calibration, the black Range Selector Switch is probably on the wrong setting. To adjust, stop engine, loosen the lock nut, and gently turn the sender clockwise until it touches the flywheel. Back off counterclockwise one turn, and secure with the locknut. Rust buildup between the teeth can cause signal loss from the sender. This tachometer is for a diesel or gasoline engine with a tachometer drive cable mounting point, and VDC 24 Volt systems can be accommodated with a Voltage Reducer.

Some older style tachs operate with only Ground and Sender connections. Rotary switch on tachometer back must be set to corresponding engine takeoff ratio takeoff revolutions vs. Arrow on slot must point to setting; if between settings, tach will go full scale when engine is running.

- free republican dating sites?

- Latest YBW News?

- free online dating in italy?

- Wholesale Marine and Building Supplies!

- ?

- top 20 dating websites in the world?

Sender is made for engines with a round drive tang fitting and keyway some engines have a. It will not fit slotted keyway drives.

- cancer survivors dating site?

- uranium lead radioactive dating?

- Find Boats For Sale?

The sender produces 8 pulses per revolution. Drive tang must be properly inserted in both sender and takeoff, and rotating internally. Tang must not be broken, worn, or rounded.

Get RPM form alternator

Tachometer will operate with other OEM electronic engine ignition systems. Teleflex has not tested aftermarket systems and cannot guarantee their compatibility. Arrow on rotary selector switch must point directly at setting or the tachometer pointer may go to full scale when engine is started. Tachometer switch arrow should be pointed at 4C, 6C or 8C to correspond to the number of engine cylinders.

The tachometer part number is stamped on the housing.

Register Now

Tachometer does have a "CAL" potentiometer feature to fine tune the tachometer a few hundred RPM or to sync two tachometers. I've already got a tach ordered that uses the alternator signal wire. Find More Posts by befitz. Thanked 2 Times in 2 Posts. For those of us whom are no longer members on the TDR I had to add a W-wire for my tach to work,here are basic instructions and some pictures. First-remove alternator,and remove backcover, 3 small nuts, and 1 large nut which holds plastic wire guard.

Technical Reference Manual

May have to pry gently. Second-Then remove screw from stator wire. I made short jumper wire with an eye on one end and a spade connecter for easy removal. Double heat shrink on eye end for protection. Page 1 of 2 1 2 Last Jump to page: Results 1 to 10 of Rev Counter sensing from alternator - how does this work?

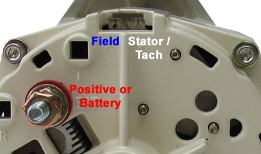

Where to connect tach in alternator

Thread Tools Show Printable Version. Having just got to grips with the alternator wiring etc I realise that one of the connections is for a Tachometer, which leads me to think I might fit one. However before going out and buying one I would like to understand how they work. Although I appreciate that the Alternator can send out some sort of pulse or current every time it completes a revolution how does a tacho know how this relates to engine revs? After all the relative sizes of the flywheel driven pulley on the engine and the pulley on the Alternator determine the ratios between engine revs and alternator revs, so how does the tacho know that 2 alternator revs or 2.

In other words if I buy one of these bits of kit have I got to very carefully work out the diameter of each pulley, do some maths and calibrate the tacho.

Is this how they work and am I missing something here? Originally Posted by Onia. I had to set the tacho for the alternator I have.